Advanced Forecasting is an often spoken about subject at an Epicor Prophet 21 related event. There is a good reason for this, its a complicated module. There are a lot of moving parts to Prophet 21 ERP’s Advanced Forecasting, and it takes time to get your head wrapped completely around the concepts. One of these concepts is the Distribution Requirements Planning or DRP feature. Users commonly have questions about when it is appropriate to turn on for a given item. This post will attempt to answer that question. Be advised, this is not a deep dive into how to use DRP, this is just about when to use DRP.

What is DRP?

DRP stands for Distribution Requirements Planning. I would be happy to quote you a very lengthy, complex definition of the term, but let’s keep it simple this time. The best way I can describe DRP is that it pulls together all of the aspects of the an item’s expected changes in on hand quantity and then puts them into a time-phased inventory forecast. It helps you visualize and answer some of the more common inventory questions on a day to day basis. Examples include:

- What is the expected usage per month between now and my next PO receipt?

- Based on current forecasts, how much inventory will I have when the next PO is received?

- I know I have plenty on order, but will any of it get here before I stock out?

- How should I structure purchase orders in order to keep a reasonable amount of stock on hand?

How Does DRP Work in Epicor Prophet 21?

Future Stock Analysis Detail

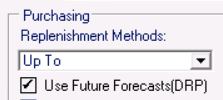

DRP in Prophet 21 ERP is enabled by check the DRP checkbox on the replenishment tab for an item/location combination. Turning it on in one location does not enable it for all locations. Once enabled, you will need to execute a re-forecast from the Demand Year Maintenance window to generate the DRP forecast for the item(s) that have been enabled.

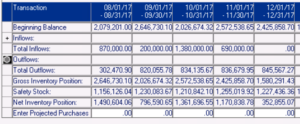

After you have a forecast, some new tabs and windows will come into play. In PORG and Item Master Inquiry, you will have access to a tab call DRP forecasts. This will show you a tabular view of the inflows and outflows of the item. There will also be a series of calculated fields that estimate the on hand inventory in each time period that is shown. In the item tab of PORG, DRP is used to calculate and display any projected shortfalls in the inventory for an item. By that, I mean a situation where you have goods on order, but they will not arrive before you are projected to stock out.

In addition to these tabs, Epicor Prophet 21 includes the Item Future Stock Analysis window and the Future Stock Analysis report that can also be used. Item Future Stock Analysis allows you to plug in planned purchase orders into each time period and calculate the impact to the on hand inventory in future months. This provides the user a detailed look at the supply chain, based upon current & future requirements, forecast usage, and any inbound goods.

When Should I Use DRP?

Frequency of Usage

This really is not as much about DRP as it is about forecasting in general. Forecasting formulas need a minimum amount of data before they really start performing with any reasonable accuracy. I have found the advice of Jon Schreibfeder at Effective Inventory Management to be pretty solid: a item needs to have usage in at least 8 out of the last 12 periods for a forecasting formula to be useful. If the item does not meet this minimum threshold, there will be too much error in the forecast. In these cases, the item should be treated as sporadic. My advice is that for these items, use a min/max. This allows you to keep some multiple of the normal month’s sales on hand. The multiple should be bigger if the item has a long lead time.

Lead Time Days

The longer the lead time, the more useful DRP can be to you. If the lead time for an item is relatively short, then DRP will not provide much value to you. The reason is that purchase receipts are happening in a very short time phase and there is not much value in looking out into the future to plan replenishment. The exact length of time that is defined as long or short is not an exact science. EIM gives a suggestion of 21 days or longer as a good benchmark. Again, I would tend to agree, though I might personally extend that out to 30 days or longer.

DRP is also very useful in a situation where you have mixed lead times. This typically occurs when you have multiple suppliers for the item, each with a different lead time. For instance, maybe there is a primary supplier with a long lead time and a secondary supplier with a short lead time. DRP would allow you to see when goods are due and when a projected stock may occur. This would help you make a decision about when to buy from the shorter lead time supplier.

Last Thoughts on Epicor Prophet 21 DRP

Hopefully, this has helped you understand where DRP might fit into your purchasing strategy. It is a useful tool when applied properly and under the right conditions. The two primary conditions I would recommend that you consider are number of months with usage and lead time. If these two meet the criteria above, then DRP in Epicor Prophet 21 might be the right fit. If not, then you will likely be better off using another option.

Read More about Epicor Prophet 21