The Epicor Prophet 21 Forecasting system has a lot of moving parts. It is definitely one of the most complicated parts of the P21 ERP system in my opinion. It seems like every time I dig into it, I find something else that I did not know was there before. With all of these settings and options, how do you know which are the most important. Are you comfortable with what each of these settings do? If you change a setting in the Prophet 21 forecasting system, do you know how it will affect the buying calculation?

What is the Review Cycle?

Whenever I am talking to Prophet 21 forecasting users about replenishment, I always try to ask for a show of hands for who knows what the definition of the term review cycle is. It never fails, no one ever speaks up. This is not just a Prophet 21 problem. Review cycle tends to be a very misunderstood setting in any replenishment system. I think part of it must be the name. It is a generic term. To make it worse, if you search for review cycle on the Internet, the first page of results does not event pertain to inventory management. This is unfortunate, as review cycle is a key input into any time-phased replenishment calculation.

The best way I have found to communicate the concept of review cycle is to describe it as follows:

- How often do you ideally want to buy from this supplier?

- How many days of inventory do you want to plan to buy at a time?

Think of the review cycle as the middle part of the calculation. On the ends, you have lead time and safety stock. Those answer the questions: “How long to get a shipment?” and “How much extra do I carry”. The stock bought by the review cycle part of the calculation is designed to cover your needs until the next time you review requirements for the vendor.

How Do I Decide on Review Cycle Days?

Once you have a clear understanding of review cycle, the next issue becomes deciding what number of days to set for a review cycle. Generally speaking, this is actually pretty straight-forward. The answer is tied to freight terms, or freight costs if you have no freight allowed terms with the supplier.

As a buyer, one thing you want to do is minimize freight costs. Inbound freight is a direct deduct from profit, so you do not want to pay any more than you have to. However, there is another side to this coin. Once you have met your freight allowance, there is no further incentive at a supplier level for buying more inventory. Freight cannot get cheaper than zero. Buying double the freight allowance amount doesn’t benefit you. That said, free freight is not always free. (Great article on this here) You do not want to buy so much inventory that you are sitting on it forever. As with all things, it is a balancing act.

Calculate the Review Cycle

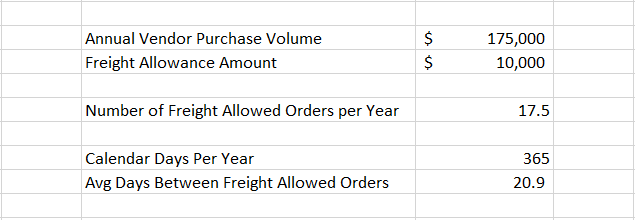

To calculate the optimal review cycle, you need to determine the average number of freight allowed orders you can place with a supplier over the course of a year at the location level. Using that information, you can then determine the optimal number of review cycle days. Consider the example shown below:

In this case, based on the annual purchases and supplier freight policy, you would place 17.5 freight allowed orders per year, or 1 order approximately every 21 days. This 21 days becomes your review cycle. This calculation works for any target type. If your vendor target is based on weight, look at how much weight you buy per year. Same goes for any unit of measure, such as pallets, containers, etc.

If there is no freight policy, then consider how to minimize freight costs. For instance, a full truckload shipment has a fixed cost. The trucking company’s charge is the same whether it is full or 75% full. This means the more goods or value you can move in that fixed cost, the cheaper the freight is on a per unit basis. In this case, you would calculate the number of full truckloads per year you can purchase.

Very Short and Very Long Cycles

There are times when the review cycle calculation is so long or so short, that using the calculation above may not make sense. I have seen times when the review cycle calculation produces numbers less than 1 or greater than a year. What do you do then? Does a daily review cycle make sense? Does buying once a year make sense?

The answer, unfortunately, is “it depends”. It is a situational question and you have to look inside your business to see what makes sense. If a buyer is having to do a full line review daily, this can get expensive from a labor perspective when you look at purchasing, receiving and accounts payable functions. In this case, I would not recommend setting the review cycle lower than about 4 days. This allows you to look at the vendor line once or twice a week and strikes a decent balance.

On the other hand, if you can only generate 1 or 2 freight prepaid orders per year for a vendor, there is another problem. Buy only ordering every 6 to 12 months, you lose a lot of flexibility to react to variability of demand. In this case, I would recommend spending some time working with others in the organization to make sure there is a clear understanding that freight targets are not readily going to be met, so it is critical to make sure the profitability of the item makes sense for this condition. As far as a review cycle for this, I would set it somewhere between 30 and 60 days. This would allow me to look at it periodically, even if I choose not to place an order. You do not want the review cycle so far out that you miss a change in demand.

Prophet 21 Forecasting: Where to Set Review Cycle

The reason that setting the review cycle on a location basis is important is because purchase volumes are likely going to be different from location to location, and you want to have the right setting in place for each warehouse.

Spend the time to get your review cycles correct in the Prophet 21 forecasting system. If you do this, you should start to see the buying calculations make more sense, and hopefully, you will also find that your purchase orders are more meaningful.

I also recommend checking this setting for your key vendors once or twice a year to make sure they still make sense for your buying practices.

For more articles on P21, visit our Prophet 21 Knowledge Base.